Featured Products

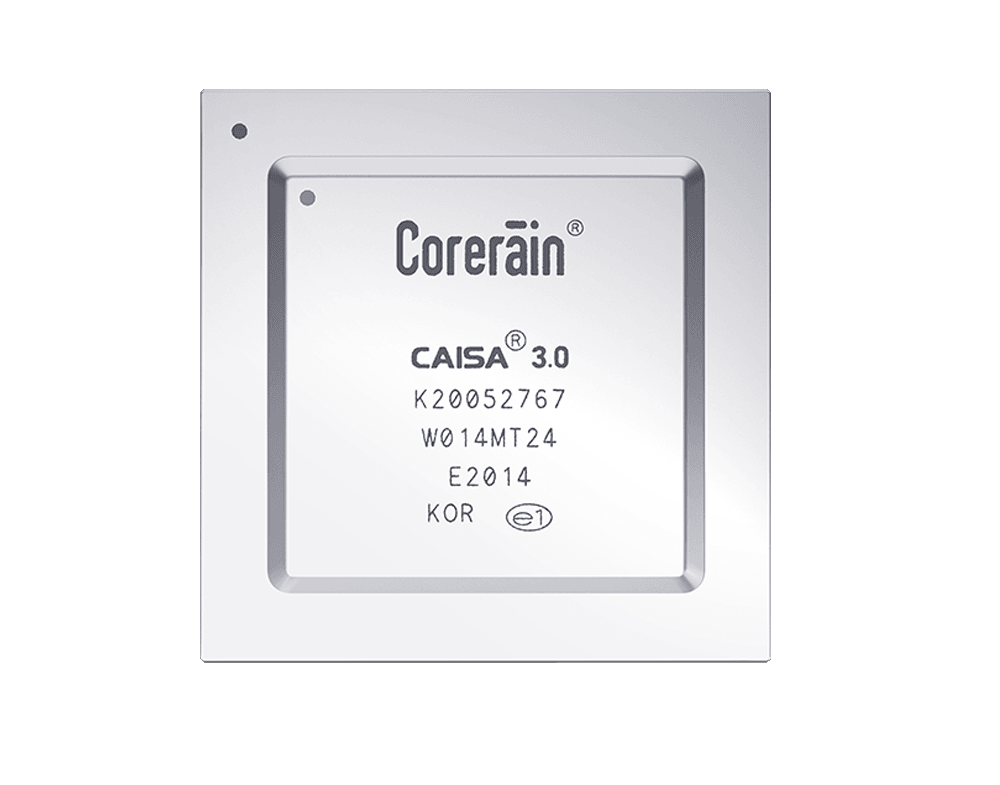

AI Chip

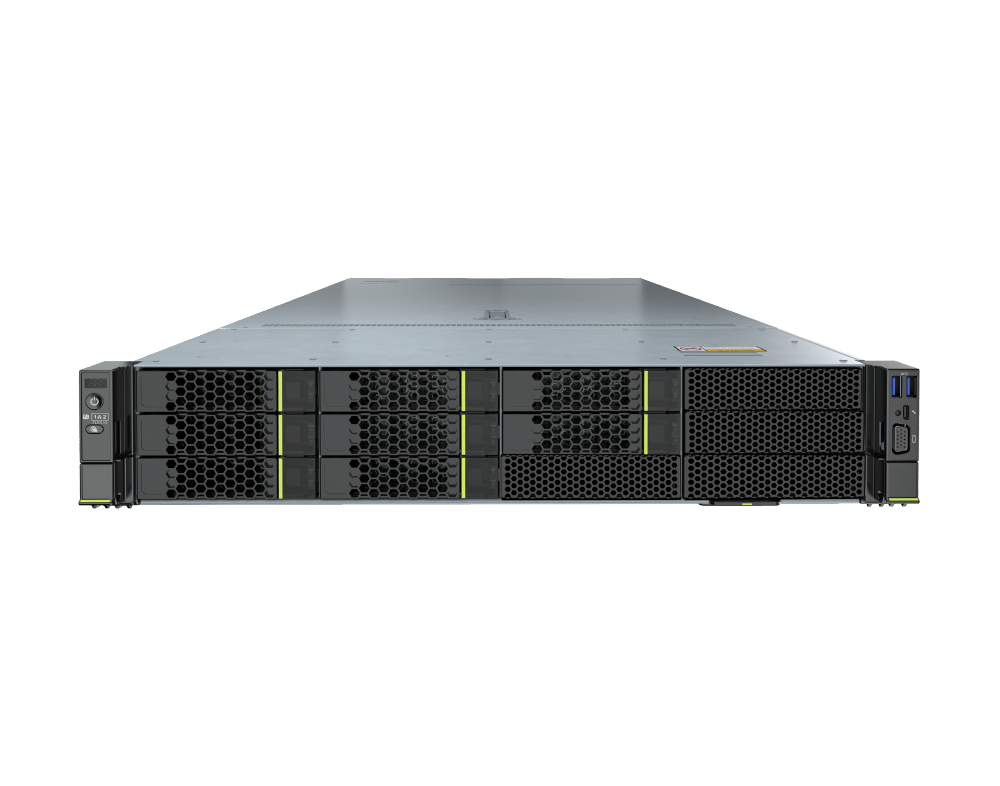

AI Accelerator

AI Edge Station

Contact Sales:(+86)19925316438

Consult Now- AI Visual Intelligence Analysis

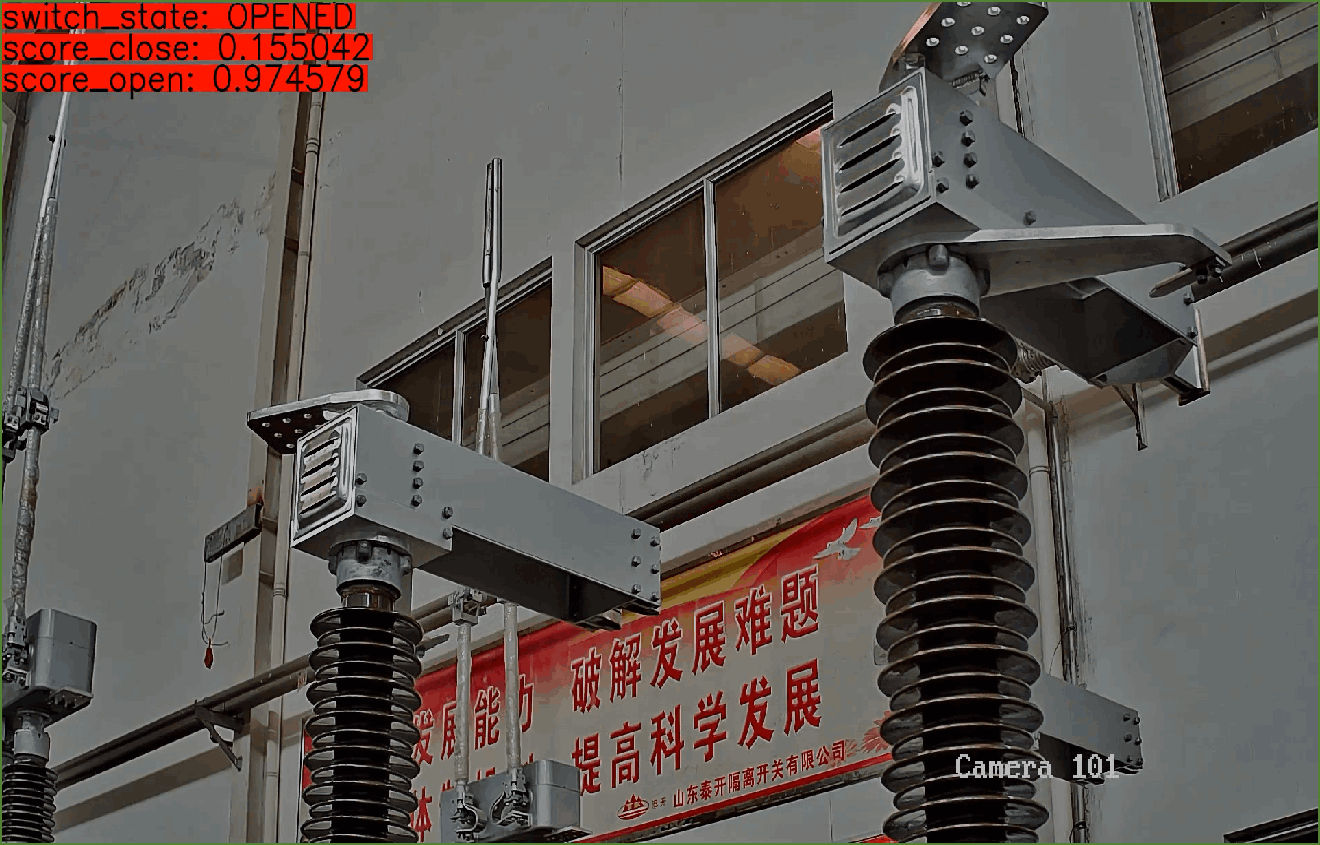

- Smart Energy

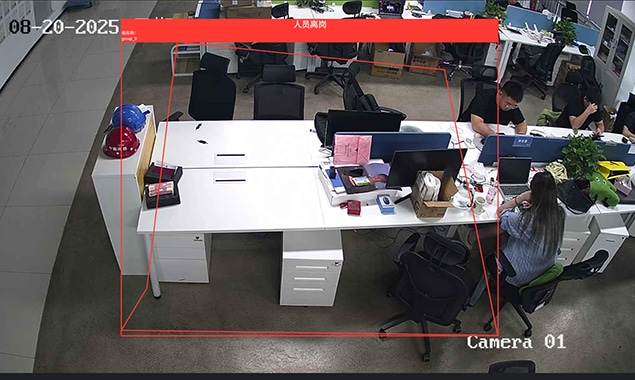

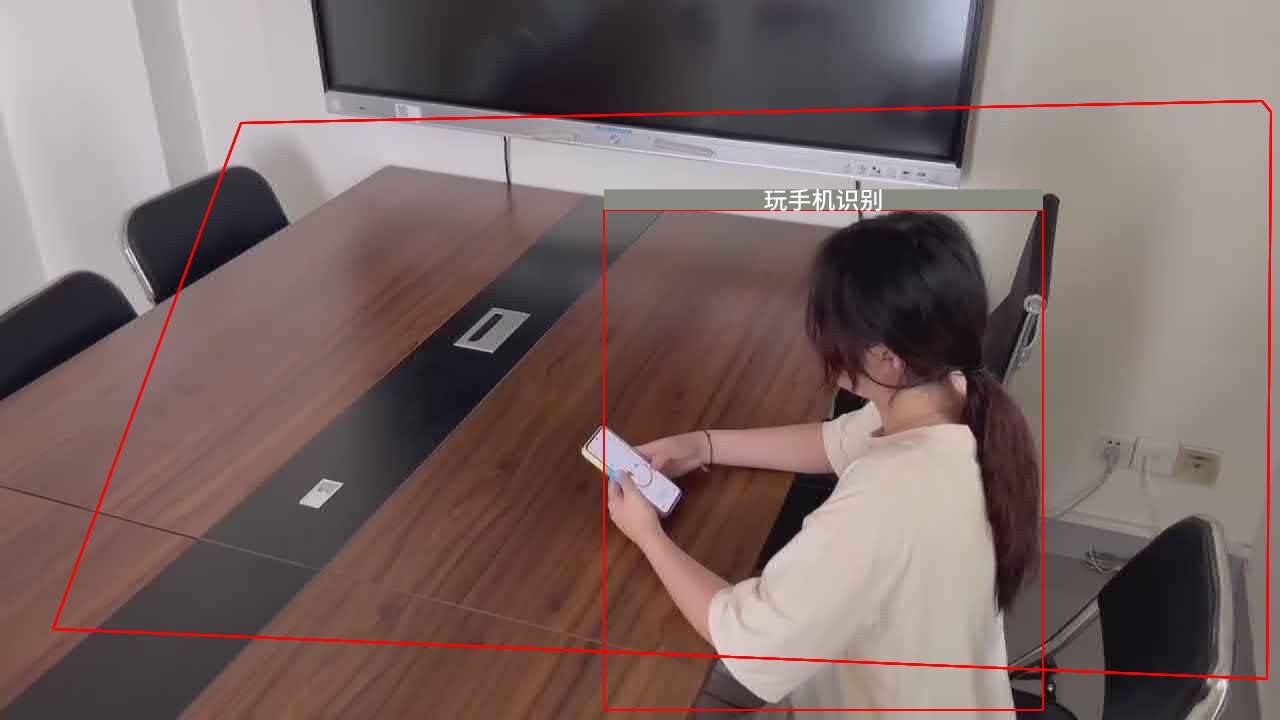

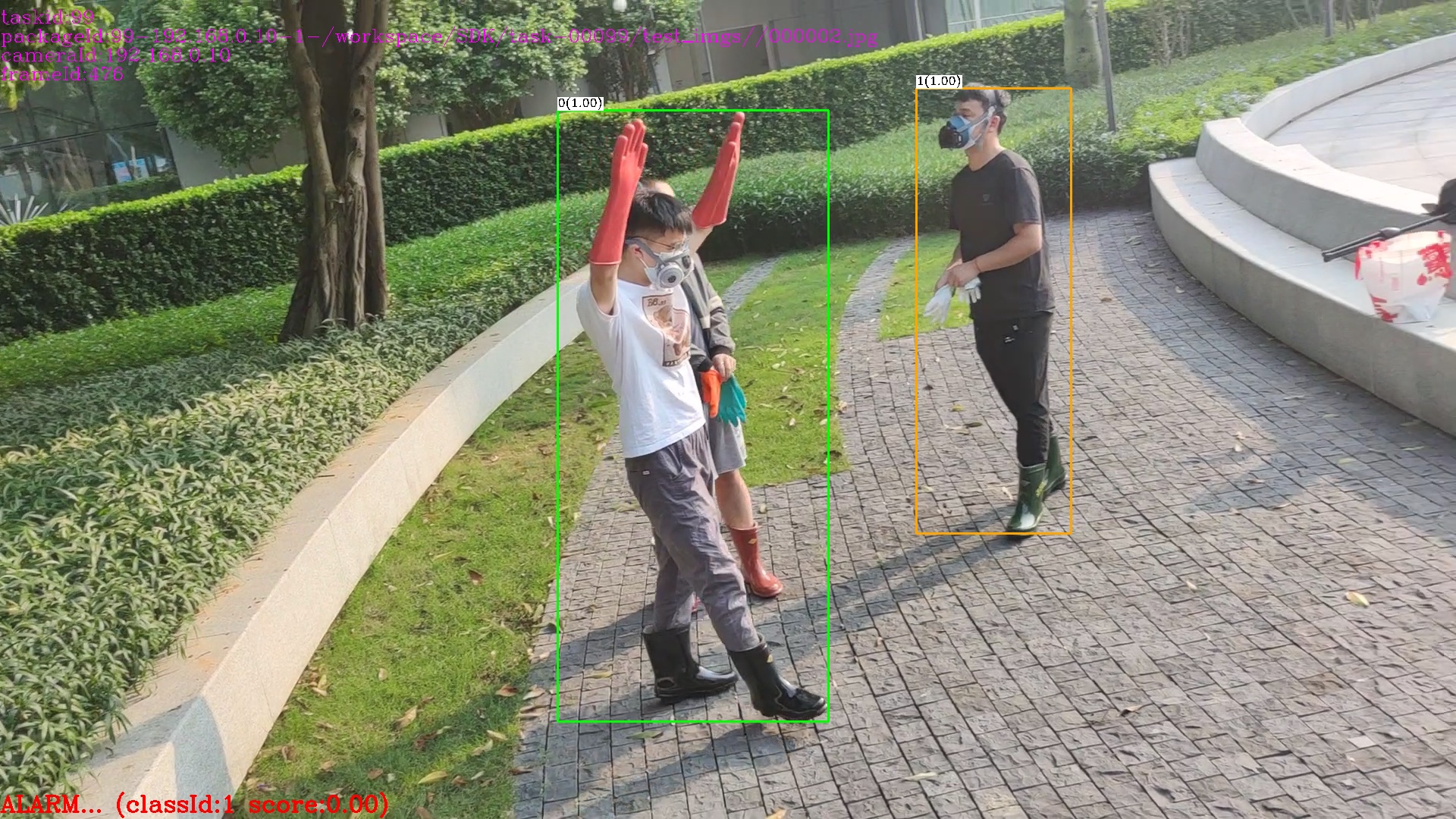

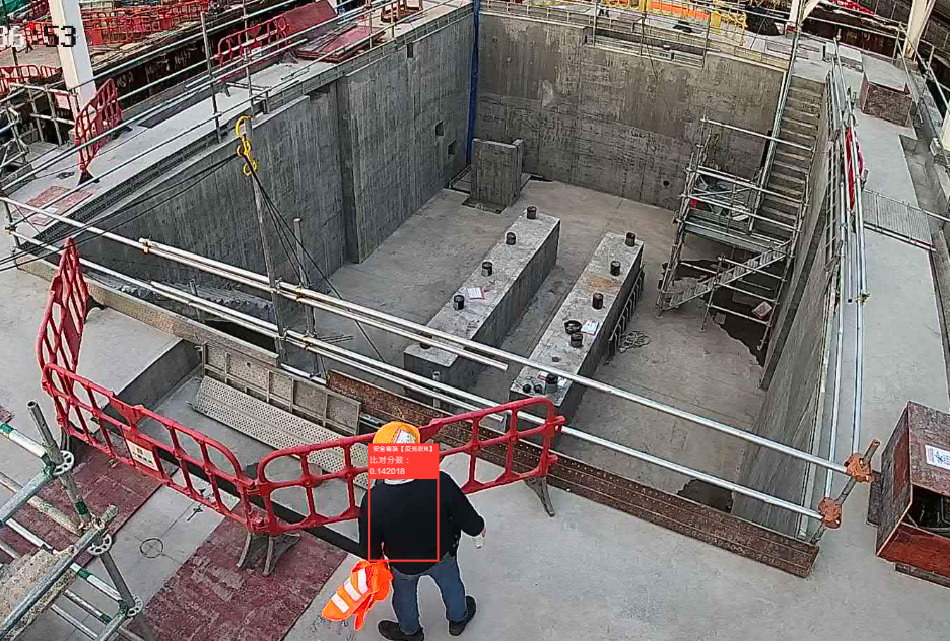

- Smart Safety Supervision

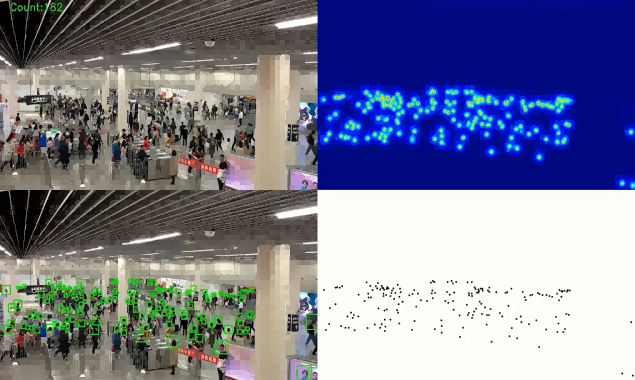

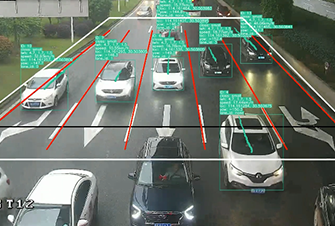

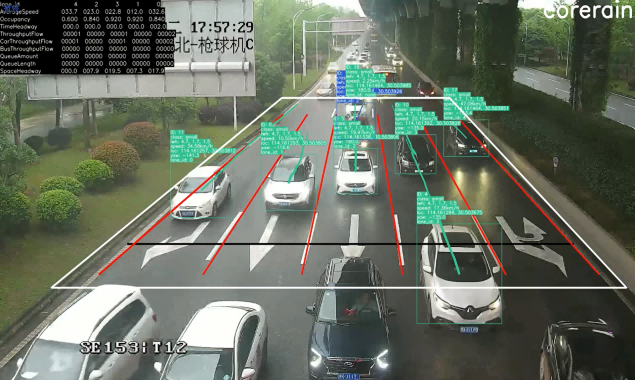

- Smart Transportation

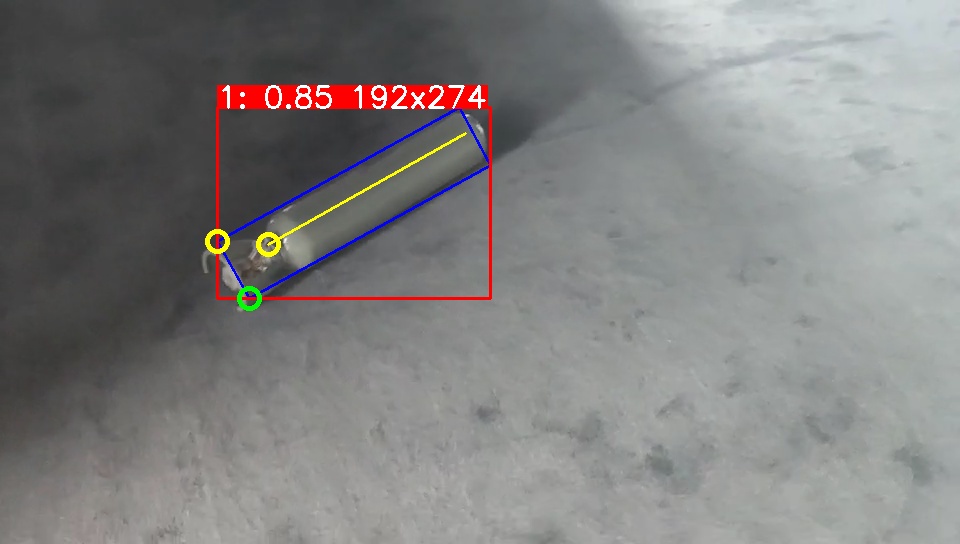

- Smart Manufacturing

AI Edge Station

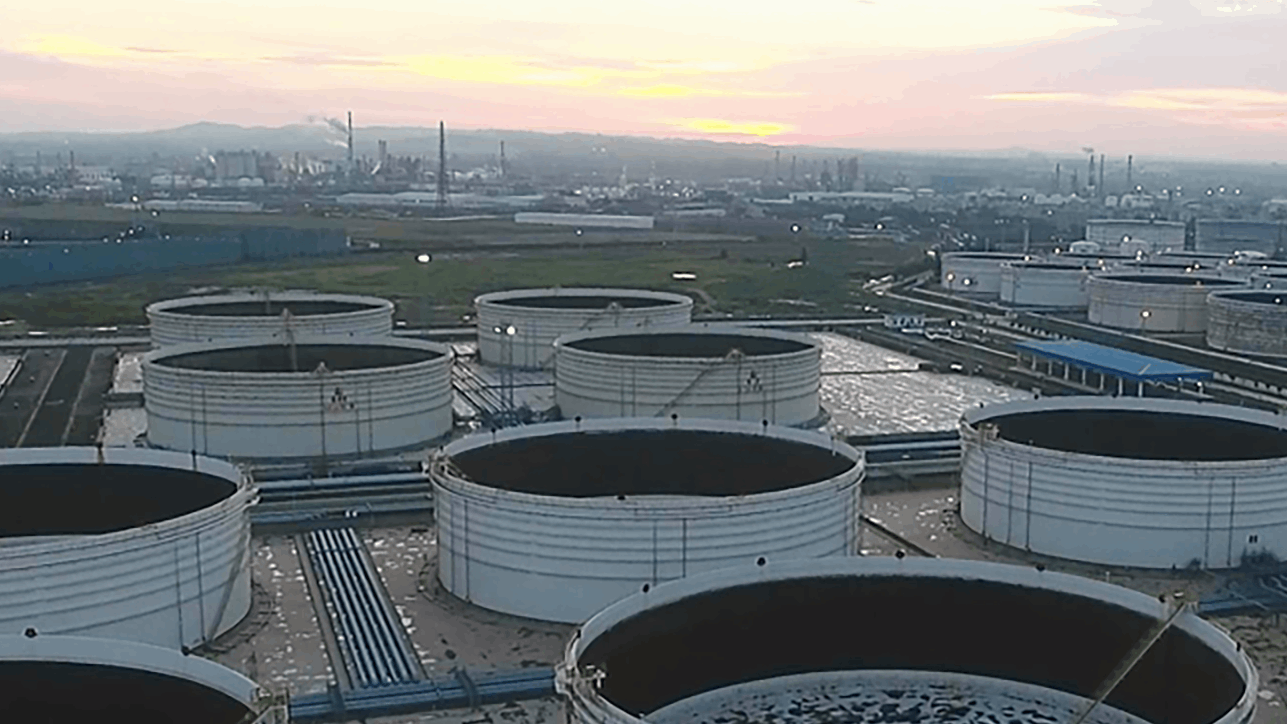

Smart Oilfield

Smart Chemical Industry

Smart Mining

Smart Gas Station

Smart Factory

Smart Construction

Smart City Governance

Smart Warehouse

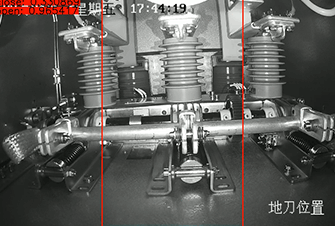

Smart Grid

Smart Commercial Complex

Smart Port

Smart Expressway

Smart Metro Station

Smart Business Hall

Smart Metallurgy

Smart Park

Surface Inspection

Smart Energy

Smart Safety Supervision

Smart Manufacturing

Contact Sales:(+86)19925316438

Consult NowAbout Corerain

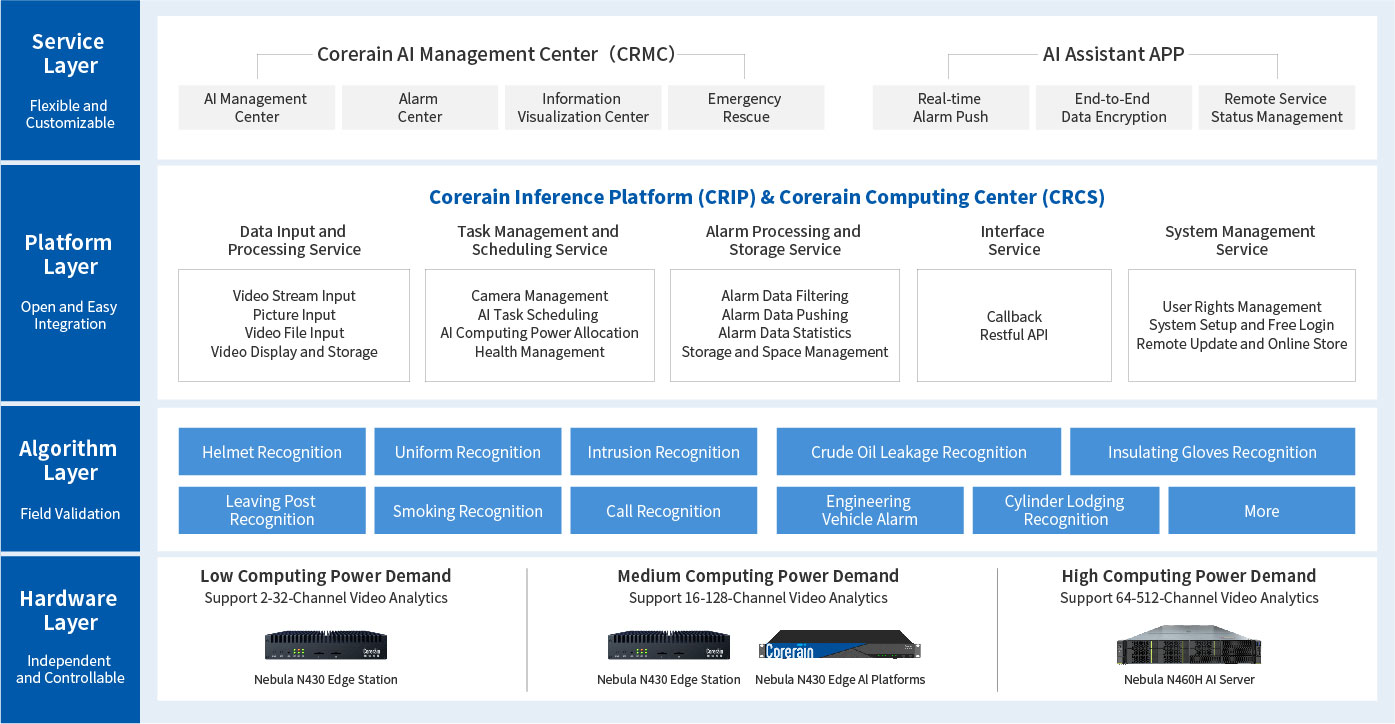

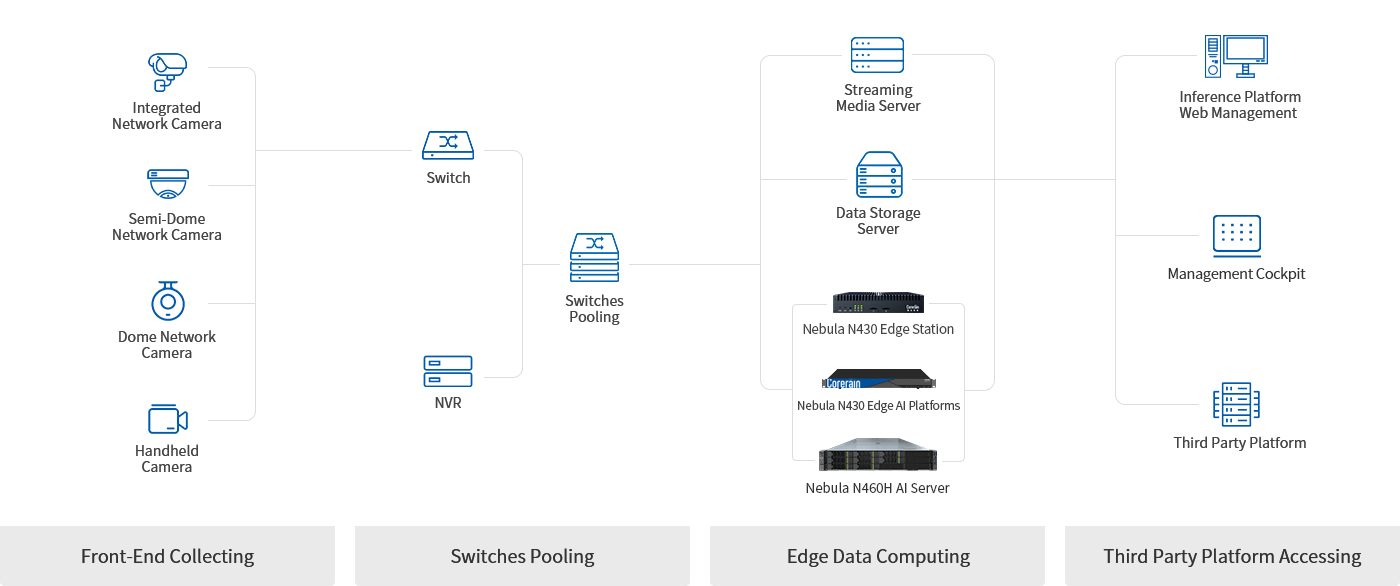

Corerain Technologies is a leading Artificial Intelligence (AI) chip and solutions company, specializing in pioneering reconfigurable streaming AI chip technologies and providing integrated hardware and software turn-key solutions for smart cities, smart energy, EHS management and smart manufacturing.

Contact Sales:(+86)19925316438

Consult Now

Call Us

Call Us

Cooperation

Cooperation

Top

Top